-

E-mail

canye8654065@gmail.com

E-mail

canye8654065@gmail.com

-

Call Us

0086 13641173523

Call Us

0086 13641173523

E-mail

canye8654065@gmail.com

E-mail

canye8654065@gmail.com

Call Us

0086 13641173523

Call Us

0086 13641173523

2020-03-06 Views: 9035

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

Quartz is generally associated with hydrothermal alteration at low and medium temperatures, under which gold is easily enriched to reach industrial grade. That’s why quartz vein gold deposits are formed. The appearance of quartz vein gold ore is generally grayish yellow and white, and the internal structure is mostly medium-fine grains, with a disseminated structure. The ore minerals are mainly chalcopyrite, pyrite, sphalerite, natural gold, and gangue minerals are mainly quartz, calcite, feldspar, etc. Chalcopyrite and pyrite are mostly distributed in plaques in quartz veins. Quartz vein gold ore is common in nature and its extraction has great significance to economic development. The following article will explore what is the most suitable process for quartz vein gold processing through analyzing a case of the quartz vein gold processing test.

A typical quartz vein gold ore was selected as the sample ore. The main useful mineral is gold, followed by a small amount of silver and pyrite, and the main gangue mineral is quartz.

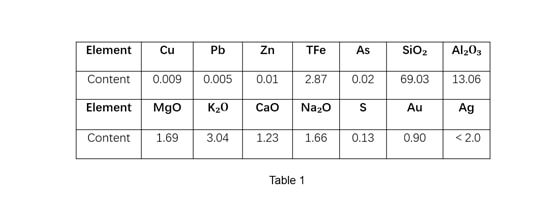

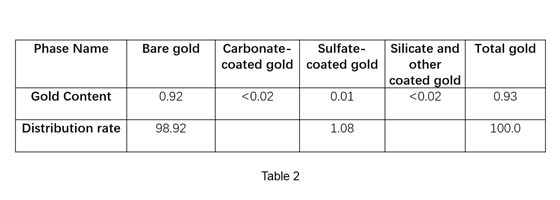

The results of chemical multi-element analysis of raw quartz vein gold (Table 1) and phase analysis results (Table 2) are shown in the following tables. The main valuable element recovered in the ore is gold with a grade of 0.9 g / t. The results of phase analysis show that the quartz vein gold is dominated by bare gold. The content of other metal minerals is relatively small, mainly pyrite, with a grade of 0.1%. The gangue minerals are mainly quartz, sericite and sodalite.

[/caption]

[/caption] [/caption]

[/caption]In the raw quartz vein gold ore, the gold minerals are mainly single gold, partly formed into fine veined toxic sand, and are wrapped by pyrite. A small amount is associated with gangue and limonite. The -2mm raw ore screening analysis results show that most of the gold in quartz vein gold ore is distributed in the coarse-grained grade, the metal distribution rate in the + 74um grade is 87.87%, and the metal distribution rate in the -37um grade is 2.51%. When the ore-74um accounted for 50%, the monomer dissociation degree of gold minerals was 86.3%, 9.9% was continuously associated with gangue, 3% was continuously associated with poisonous sand, and 0.8% was continuously associated with pyrite. The Kenbo granularity of gold minerals is relatively coarse, with a particle size of more than 100um accounting for 65.9%, and a particle size of less than 40um accounting for 13%.

According to the nature of the quartz vein gold ore, three kinds of gold processing tests were performed:

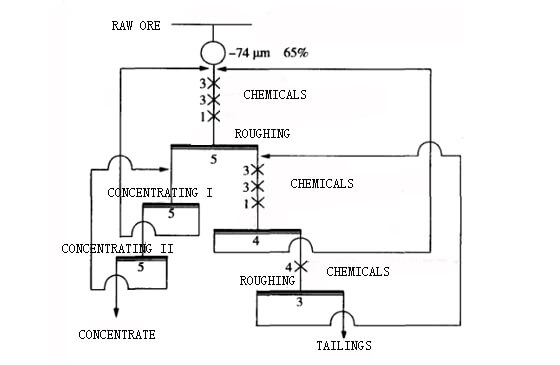

First, a flotation test was performed to determine the appropriate flotation chemical system, grinding size and flotation time. Based on this, one stage roughing, two stages concentration, and two stages scavenging flotation process was applied. As shown in the following flowchart.

flotation process[/caption]

flotation process[/caption]The final gold concentrate production rate was 0.93%, the grade reached 96.8g / t, and the recovery rate was 95.77%. The gold processing effect is good, but there is a phenomenon of coarse-grained gold sinking in flotation cell, which has a certain impact on the gold concentrate index.

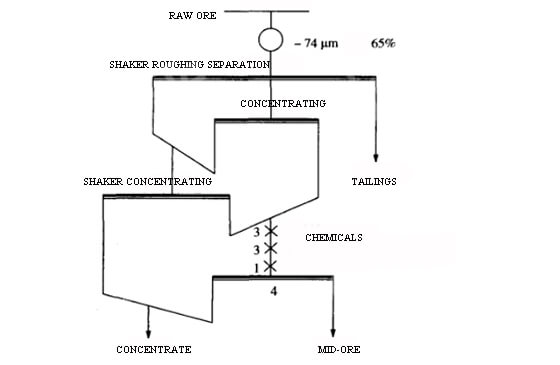

Gravity separation process is a traditional method that can recover granular gold without pollution. But it have the disadvantages of low enrichment ratio and small capacity. In the gold processing test of quartz vein gold ore, a shaker separation was performed first, and then gold concentrate was floated by flotation process. The gold processing test flowchart is shown in the table below.

shaker separation and flotation process[/caption]

shaker separation and flotation process[/caption]Finally, the combined grade of the concentrate obtained through the combination process of gravity process and flotation process was 133.77 g / t, the recovery rate was 91.32%, and the tailings loss rate was 6.09%. The gold processing test results showed that the combined process of shaker separation and flotation can recover gold better.

Firstly, the grinding fineness test and the Nelson gravity multiple test were performed to determine the best grinding fineness and the best gravity multiple respectively. After determining the two major factors, the combined gold separation process of Nelson, shaker separation and flotation process test was started.

In the test, the quartz vein gold power was first processed by Nelson, and then the obtained coarse concentrate was processed by a shaker. In order to reduce Nelson tailings losses, flotation of Nelson tailings is performed. Nelson gold gravity process can recover coarse-grained gold. Nelson gravity process concentrate production rate was 1.19%, grade reached 64.03%, and recovery rate was 86.58%. The concentrate grade obtained through the shaker separation process was 480.60 g / t, and the recovery rate was 83.34%. Through the flotation of Nelson tailings, the gold concentrate grade was 11.2 g/t and the recovery rate was 10.97%. Therefore, the total recovery rate of this process reached 94.31%.

Comparative analysis of the three process for quartz vein gold processing

1. The single flotation process has better flotation indexes with 95.77% recovery rate and 96.8g/t concentrate grade. It is recommended for quartz vein gold ore with small mud content and no coarse-grained gold. However, for the quartz vein gold ore with high mud content and coarse-grained gold like the sample in the article, using a single flotation process will make the gold concentrate grade lower than that of gold recovered by gravity process. So, a single flotation process is not recommended in this case.

2. The recovery rate of gold in the combined process of shaker separation and flotation process test reaches 91.32%, and the concentrate grade is 133.77g / t. The shaker can better recover gold, which is beneficial to reduce the loss of gold in the tailings. This process is recommended for small-scale gold processing plants. However, for medium or large-scale gold processing plants, in view of the small processing capacity of the shaker, the large footprint, the high requirements for the plant and high investment, it is not recommended to use the shaker separation process.

3. The recovery rate of gold in the combined process of Nelson, shaker separation and flotation process test reaches 94.31%, and the concentrate grade is 480.60g/t. Nelson has a large processing capacity and a small equipment footprint, which can save gold processing plant space and prevent coarse gold from sinking. Therefore, for quartz vein gold ore with more granular gold, this process is recommended. Through comparative analysis, for the quartz vein gold processing in the test, the processing index of this process is the most ideal.

Through the quartz vein gold processing test, it can be seen that the three processes of single flotation, the combined process of Nelson, shaker separation and flotation, the combined of shaker separation and flotation can better recover the gold in the raw ore. However, the three processes each have their own characteristics . The specific process for quartz vein gold ore also needs to be comprehensively considered according to the nature of the ore, the area of the gold processing plant, and the investment situation. It is recommended that you find a professional gold processing service provider and gold processing agent manufacturer with laboratory qualifications to maximize the overall benefits through scientific processing solutions and beneficiation chemical systems.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!