-

E-mail

shirleyyin321@gmail.com

E-mail

shirleyyin321@gmail.com

-

Call Us

0086 18716000713

Call Us

0086 18716000713

E-mail

shirleyyin321@gmail.com

E-mail

shirleyyin321@gmail.com

Call Us

0086 18716000713

Call Us

0086 18716000713

2020-03-25 Views: 2014

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

Cyanide leaching process is one of the common gold ore beneficiation processes. The process index depends on factors such as gold particle size, sulfide content, ore block size, leaching speed, leaching time, cyanide concentration and leaching slag washing degree. The factors that affect gold leaching include grinding fineness, pH, temperature, cyanide dosage, pulp-solid-liquid ratio, leaching time, impurities in ore and amount of leaching aid and so on. This article will discuss how grinding fineness influence gold leaching process and its related problems and improvement methods.

Grinding fineness refers to the thickness of the grinding product, and is usually expressed by the mass fraction (%) of the ore particles less than 200 mesh (less than 0.074 mm) in the total grinding product.

In general, the determination of grinding fineness is related to embedded relationship of the ore. The embedded shapes and particle sizes of different ore have an impact on the determination of grinding fineness. Take a gold mine as an example and do related gold leaching experiments:

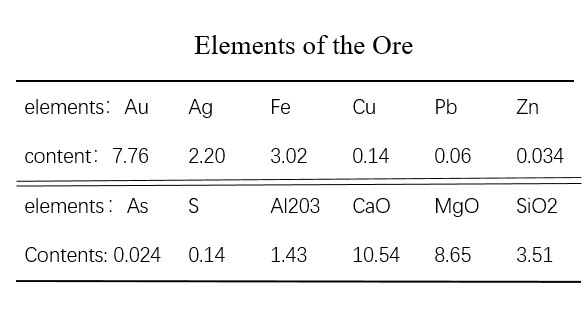

The main metal minerals in this gold ore are natural gold, pyrite, hematite, limonite, poisonous sand, etc., and the gangue minerals are mainly dolomite, malachite, quartz, mica, etc. The main elements of its ore are as follows:

The whole test of gold leaching process: first pour the raw ore ground to a certain fineness into the JT-80 type leaching mixing tank, then add a certain amount of sodium cyanide, adjust the mass concentration of the pulp to 33%, and then add lime to adjust the pH to 11.5. After leaching at 18°C for a certain period of time, aspirate the supernatant liquid, wash and dry the dross, and finally analyze the gold grade of the dross to calculate the gold leaching rate. Here we judge the leaching effect by comparing the gold leaching rates.

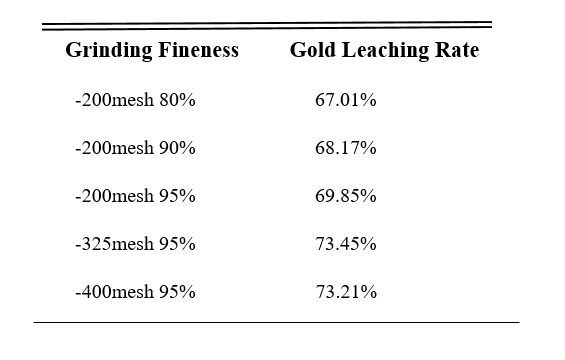

The grinding fineness test was carried out under the condition that the amount of sodium cyanide was 1 kg / t and the leaching time was 24 hours. The results were analyzed by observing the effects of different fineness on the gold leaching process. The following sets of data were obtained in the experiment:

From these sets of data, it can be seen that the grinding fineness has a greater impact on the gold leaching rate. With the increase of the grinding fineness, the gold leaching rate increases first and then slowly. It can indicate that increasing the grinding fineness is beneficial to release of gold minerals from the inclusions. Take into comprehensive consideration, a 325 mesh accounted for 95% is a more suitable gold leaching grinding fineness.

The above experiment can determine that a 325 mesh accounted for 95% is a more suitable gold leaching grinding fineness. However, in the actual gold leaching operation, the grinding fineness will also be affected by other factors, which will indirectly affect the gold leaching results. Therefore, how to avoid or reduce these problems is also important. The following are the factors that affect grinding and the methods to improve them.

Crushing particle size and grid sieve adjustment: Crushing particle size and grid sieve adjustment are also one of the factors that affect the grinding fineness in the gold leaching process. This requires the ball miller to do a good job of the supervision of the crushing system. If the grain size of the ball mill changes during production, it must be reflected to the crushing workshop immediately. Ultimately, the crushing particle size is required to meet the requirements of the mill to reduce the power consumption of the ball mill.

Blade wear of the ball mill classifier: When we start gold leaching process, we should do a good job of the supervision of machine, especially classifier. Because when the blades of the classifier are worn, the amount of returned sand will decrease, resulting in coarser grinding fineness. Even affecting the life of the classifier. When buying a ball mill, we should pay attention to consulting the ball mill speed, classifier speed, and classifier impeller spacing.

Classifier overflow dam height setting: The classifier overflow dam height affects the size of the ore sedimentation area, which indirectly affects gold leaching process. In actual production, if the fineness of the ball mill is required to be finer, we can weld a certain height of angle irons on both sides of the classifier, and adjust the height of the classifier overflow dam by cutting wood.

Classifier opening settings: The openings under the classifier are large and low, which will cause the amount of returned sand to be large, and the fineness of the ore is relatively fine; the openings on the classifier are large and low, which will also cause the amount of returned sand to be relatively large and fine Relatively thinner. So it is important to adjust the classifier opening before starting gold leaching process. Generally, the size of the upper and lower openings of the classifier is produced on site during the installation of the equipment, which requires preparation in advance during installation.

In short, in the gold leaching process, grinding fineness directly affects the final gold ore recovery rate. So for different gold ore, we must determine the corresponding grinding fineness through ore dressing tests. At the same time, we must ensure that the equipment is installed in good condition and workers operate correctly in actual production. Then we can better operate gold leaching process.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!