-

E-mail

canye8654065@gmail.com

E-mail

canye8654065@gmail.com

-

Call Us

0086 13641173523

Call Us

0086 13641173523

E-mail

canye8654065@gmail.com

E-mail

canye8654065@gmail.com

Call Us

0086 13641173523

Call Us

0086 13641173523

2019-12-21 Views: 6200

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

Before the introduction of MIBC. We should know that most of the minerals in nature have very poor floatability. It is necessary to add a flotation reagent to selectively change the floatability of the mineral, so that the flotation behavior of the mineral can be controlled artificially. Foaming agent is exactly an important member of the flotation agent.

The foaming agent mainly acts on the water-air interface, which promotes the dispersion of air into small bubbles in the pulp, prevents the merger of the bubbles, and improves the stability of the bubbles during the mineralization and floating process, ensuring that the foamed layer is formed after the mineralized bubbles float.

In actual production applications, foaming agents are mainly divided into natural foaming agents and artificial foaming agents.

Natural foaming agents include pine oil, camphor oil, eucalyptus oil, 2# oil, and phenol or cresol acid obtained from coal tar processing. As we all know, pine oil is the most widely used In flotation process. Pine oil is processed from turpentine. Its main component is terpene alcohol. It has strong foaming ability, uniform foam size, and medium viscosity. At high dosages, the foam becomes fine and sticky, affecting the concentrate grade.

Synthetic foaming agents are obtained through a series of chemical processes. Compared with natural foaming agents, artificial foaming agents have the advantages of better flotation performance, stable sources, low price and high flotation efficiency. Methyl isobutyl methanol (MIBC) is a typical representative. With the development of beneficiation technology, MIBC has also become the new darling of flotation plants.

First, methyl isobutyl methanol (MIBC) is a synthetic fatty alcohol foaming agent, a colorless transparent liquid, slightly soluble in water. Here is a brief introduction to MIBC:

Product Name: Methyl Isobutyl Carbinol Molecular Formula: (CH3)2CHCH2CH(OH)CH3 Other Name: Methyl amyl alcohol; 4-Methyl-2-pentanol; Isobutyl methyl carbinol; MIBC; Metilisobutilcarbinol. Appearance: Colorless liquid Package: Plastic drum, net weight 165KG/drum or 830KG/IBC Application: Used as a good foaming agent for lead-zinc, copper and molybdenum ore, copper and gold and non-metallic mineral. Storage: Store in a dry, cool and ventilated place.

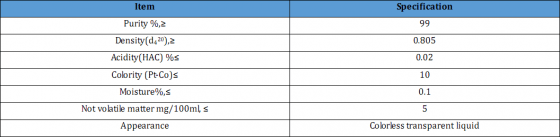

(Specification of MIBC)[/caption]

(Specification of MIBC)[/caption]1. Prevent bubbles from merging, so that the bubbles dispersed in the pulp have a smaller diameter and a certain life.

2. Increase the mechanical strength of the bubbles.

3. Decrease the movement speed of bubbles and increase the residence time of bubbles in the pulp.

4. Stable bubbles. The type and amount of bubbles affect the size, viscosity and brittleness of the bubbles and the flotation speed.

5. Co-adsorb with the collector on the surface of the ore particles and play a synergistic role.

6. Coexisting with the collector in the micelles, affecting the critical micelle concentration of the collector.

7. Foaming agent can be used to emulsify the collector or accelerate the dissolution of the collector.

8. It can increase the selectivity of the flotation process.

Compared to Pine oil, what are the advantages of MIBC as a foaming agent? The test shows that it is characterized by strong foaming ability, low dosage and good selectivity. In the flotation process, MIBC is used as a foaming agent, with uniform bubble size and moderate toughness, which is conducive to improving the concentrate grade.

For its advantages, it may be a good choice to use MIBC as a ore flotation frothers in your processing plant.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!