-

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

-

Call Us

008613641173523

Call Us

008613641173523

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

Call Us

008613641173523

Call Us

008613641173523

2026-01-30 Views: 82

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

Got a low-grade gold deposit that won't make money with traditional mills? You're not alone. Many small and medium mine owners in South Africa, Nigeria, and across Africa sit on ore grading between 0.3 to 3 grams per tonne. Sending that rock to a CIP or CIL plant burns more cash than the gold is worth.

Heap leaching changes the game. It's the most cost-effective way to pull gold from low-grade ore, and you can start production in weeks, not years.

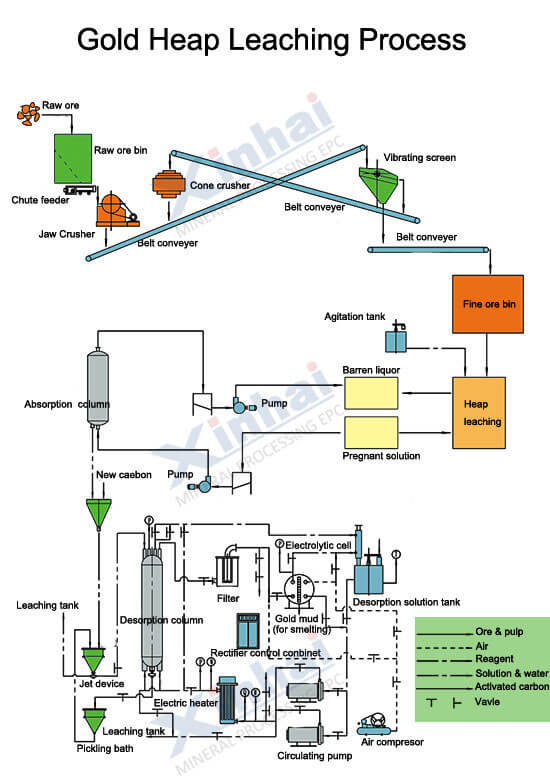

Imagine making a big pile of crushed rocks on a plastic sheet, then sprinkling a special liquid on top. The liquid dissolves the gold and drips down to the bottom, where you collect it. You then pull the gold out of that liquid using carbon or zinc.

That's it. No massive grinding mills. No expensive tanks. No complicated infrastructure.

The method works best for oxidized ores – the reddish or brownish dirt rocks you often find near the surface in African mines. If your ore is porous and the gold particles are small, heap leaching can recover 60% to 85% of your gold.

You don't need an engineering degree to understand this process. Here's exactly what happens:

You break the ore to the size of your fist (30-50mm). Don't make it dust – that blocks water flow. Just fist-sized chunks.

Find a gentle slope (like a hillside with 3-5 degrees tilt). Lay down thick plastic sheets (HDPE liners) to stop leaks. Add a layer of waste rock on top to protect the plastic.

Use a loader or trucks to make a pile. Keep it under 9 meters high for best results. Some big operations go higher, but start low.

Use simple sprinklers or drip pipes to spread the leaching liquid. For gold, this is usually a weak cyanide solution (pH 9.5-11) or newer eco-friendly agents that work without cyanide.

The gold-rich liquid (pregnant solution) flows into a pond. You run it through carbon columns or add zinc powder to catch the gold. The leftover liquid goes back to the pile – you reuse it again and again.

Let's talk money, because that's what matters.

A traditional CIL plant costs $5,000 to $10,000 per daily tonne of capacity. For a 100-tonne-per-day operation, that's half a million dollars or more.

A heap leach setup? Under $100,000 for the same capacity. Sometimes much less if you use local materials.

Operating costs drop too:

Heap leaching: $20-50 per tonne of ore

CIL processing: $80-150 per tonne

For low-grade ore (1 gram per tonne), you can't afford expensive grinding. Heap leaching keeps you profitable even when gold prices dip.

Yes, traditional heap leaching uses cyanide. It's cheap and works fast. But in many African countries, transporting and storing cyanide creates headaches:

Special licenses

Security risks

Community protests

Strict waste rules

The good news: New eco-friendly agents like CNLITE work just as well but aren't toxic. They handle complex ores better than cyanide, and you don't need hazardous waste permits to dispose of the tailings. This alone can save you months of paperwork and community trouble.

After visiting operations in South Africa, Ghana, and Tanzania, here is what separates successful heap leach mines from failed ones:

If your ore feels sticky like modeling clay when wet, you must add cement or lime during crushing. Skip this step, and your solution won't flow down – it will run off the sides. That's lost gold.

Heap leaching hates too much rain. Build a 0.4-meter-high ridge around your pad to stop floodwater. In the wet season, you might need to cover the pile with plastic sheeting.

Don't build a massive pad on day one. Do a 10,000-tonne trial first. Run it for 90 days and measure your recovery rate. If you get less than 65% gold recovery, your ore might need crushing finer or pre-treatment.

Even with good liners, install monitoring wells 50 meters downstream. Test the water monthly. If you catch a leak early, you fix it cheap. If late, you face government fines and community lawsuits.

Ask yourself these three questions:

Is my ore grade between 0.3g/t and 3g/t?

Is the gold visible or locked in sulfides? (Heap leaching struggles with sulfide-locked gold)

Do I have space for a flat or gently sloping pad near my mine?

If you answered yes to all three, heap leaching is likely your best choice.

Start with a small test pad. Measure your results. Scale up only what works. That's how smart mine owners build sustainable operations in Africa without breaking the bank.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!