-

E-mail

canye8654065@gmail.com

E-mail

canye8654065@gmail.com

-

Call Us

0086 13641173523

Call Us

0086 13641173523

E-mail

canye8654065@gmail.com

E-mail

canye8654065@gmail.com

Call Us

0086 13641173523

Call Us

0086 13641173523

2020-03-17 Views: 6894

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

High sulfide gold ore refers to a certain gold ore with 20% -30% of gold wrapped by sulfide (mainly pyrite). Because most of the gold in high-sulfide gold ore exists in the form of sulfide-encapsulated gold, when using direct leaching process, the consumption of gold leaching agent and cost of gold leaching production will increase, and gold processing efficiency is not good. So it is better to use gravity separation, flotation, or flotation-cyanidation process. The following is an analysis of specific beneficiation tests, and introduces four commonly used gold processing methods for high-sulfide gold ores.

The gravity separation method is a traditional and most basic method for gold processing, which is suitable not only for placer gold beneficiation, but also suitable for high sulfide gold processing.

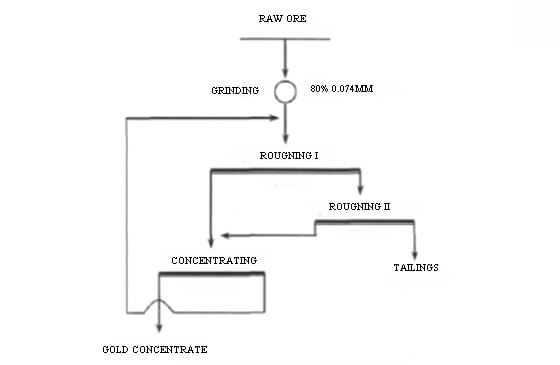

Commonly used gravity separation equipment includes shaking table, spiral chute, jig, centrifugal concentrator, etc. It is recommended to use a centrifugal concentrator for high-sulfide gold processing, because the centrifugal concentrator covers a small area, uses less energy, can recover refractory minerals, improve the recovery rate of continuous organisms, separate inclusions and remove slime. In order to reduce the loss of gold in tailings and increase the gold recovery rate as much as possible, the two roughing and one concentrating process with middle ore returning to roughing operation for reprocessing can be used, which can raise gold recovery rate to the most according to gold processing test.

First, the optimal grinding size and centrifugal force are determined by the ore grinding fineness test and centrifugal force field test. Then, the process of using two roughing and one concentrating, middle ore returned to the roughing operation for reprocessing is used for high sulfide gold processing. The process flowchart is shown in the table below. Through the centrifuge gravity separation method, the gold can be better enriched. The final grade of gold concentrate was 54.9g / t, and the gold recovery rate reached 85%. This process is relatively simple, but usually has not as high recovery rate as flotation.

(gravity separation process)

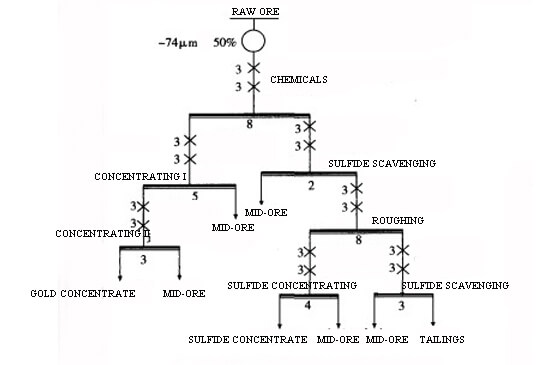

(gravity separation process)The flotation process is one of the commonly used processes for sulfide gold processing. Because flotation can maximize the enrichment of gold into sulfide concentrates. According to the nature of high sulfide gold ore, sulfide suppression flotation process is preferred.

The sulfide suppression flotation process preferentially recovers gold, which aims to maximize the recovery of gold and sulfide. Predetermined grinding size, chemical system and the process of gold processing test. Under the most suitable process parameters, the gold is recovered by one roughing and two concentrating flotation process. The crude sulfide concentrate obtained through the roughing process is then subjected to a flotation process of one roughing, one concentrating and two scavenging to recover sulfide. Finally, comprehensive recovery of gold and sulfide is achieved. The grade of gold concentrate was 56.1g / t, and the recovery rate reached 88%. The process flow is shown in the following table.

(flowsheet of the selective flotation of Auwhile drpressing S)

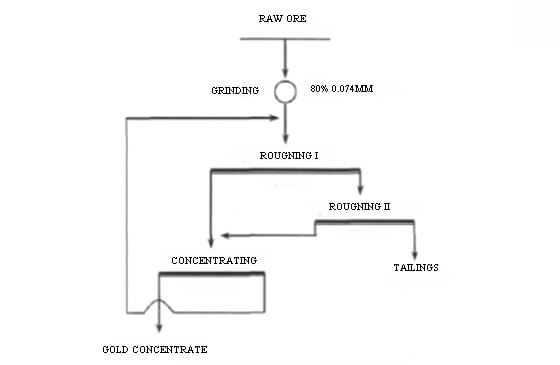

(flowsheet of the selective flotation of Auwhile drpressing S)Mixed flotation is one of the high sulfide gold beneficiation method. According to the nature of the ore and the gold processing test results, the coarse grinding-mixed flotation-regrinding- sulfide separation processes can better recover gold.

Choosing the right grinding fineness can help avoid over-grinding, which is the first prerequisite for reducing grinding costs and improving recovery. So it is important to do rough grinding test for determining the optimal particle size before separation process. After determining the optimal coarse grinding particle size, a flotation test is performed to determine the type, dosage, dosing point, and dosing method of the flotation reagent.

Under the best process parameters, one roughing-one concentrating- two scavenging flotation process is applied to obtain a mixed concentrate of gold and sulfide. The obtained mixed concentrate was subjected to fine grinding test process to determine the optimal particle size before the next flotation operation. On this basis, gold concentrate and sulfide concentrate are obtained by using one roughing-two concentrating- one scavenging flotation process. The grade of gold concentrate was 57.67g / t, and the recovery rate was 93.08%. This process achieves the comprehensive recovery of valuable sulfide while effectively recovering the gold in the ore. The gold processing flow diagram is as follows:

(gravity separation process)

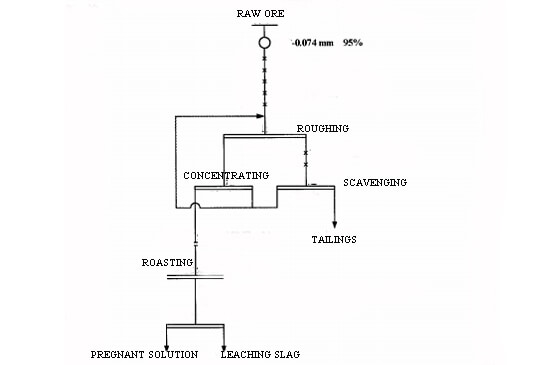

(gravity separation process)The symbiotic relationship between gold and sulfide in high-sulfide gold ore is close, and most of the gold is wrapped in sulfide, so the gold recovery rate of direct leaching will be extremely low. In addition, the consumption of gold leaching reagent is large, so as the cost of direct leaching of raw ore. Therefore, it is not appropriate to do high sulfide gold cyanidation. Taking into consideration the combined factors such as beneficiation test results and production costs and so on, it was finally determined that the flotation-roasting-cyanide leaching process was an alternative process.

On the basis of determining the optimal grinding size, the most suitable process flow is determined by flotation test as one roughing-one scavenging - one concentrating process. The gold-bearing mineral in the high sulfide ore is enriched into the concentrate by flotation, and then slaked lime and additives are added to the flotation concentrate, and the mixture is roasted after being thoroughly mixed. The roasting temperature is generally controlled at about 650 ° C. Sulfide is removed by roasting, so that the wrapped gold is exposed, and at the same time, a porous and highly permeable roasting sand that is favorable for leaching is obtained.

The roasted sand after roasting desulfurization treatment is dissolved and stirred according to a certain solid-liquid ratio, and cyanide or an environmentally-friendly gold leaching reagent is added for stirring and leaching. After the leaching is completed, gold concentrate is obtained through filtration, washing and drying operations. The grade of gold concentrate was 76.25g / t and the recovery rate reached 89%. The process flow is shown in the following figure:

(Flotation-roasting-cyanidation leaching process for high-sulfide gold ore)[/caption]

(Flotation-roasting-cyanidation leaching process for high-sulfide gold ore)[/caption]In summary, the four beneficiation processes can better recover gold from high-sulfide gold ores. When considering the gold concentrate grade and gold recovery rate, the mixed gold flotation process and the flotation-roasting-cyanidation leaching process show ideal index for gold processing. However, the specific choice of process also needs to be comprehensively considered based on the nature of the ore and the investment in the gold processing plant. It is recommended that you find a professional gold processing service provider and gold processing agent manufacturer with laboratory qualifications to maximize the overall benefits through scientific processing solutions and beneficiation chemical systems.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!