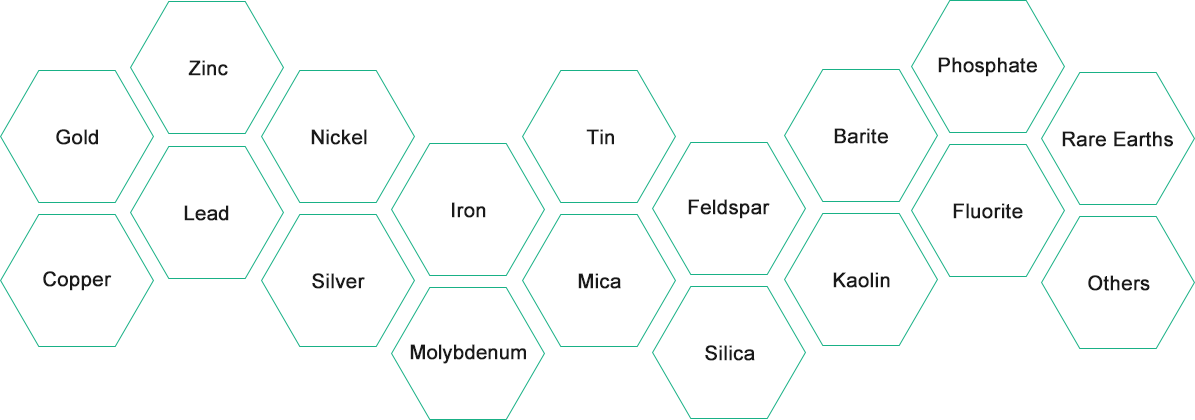

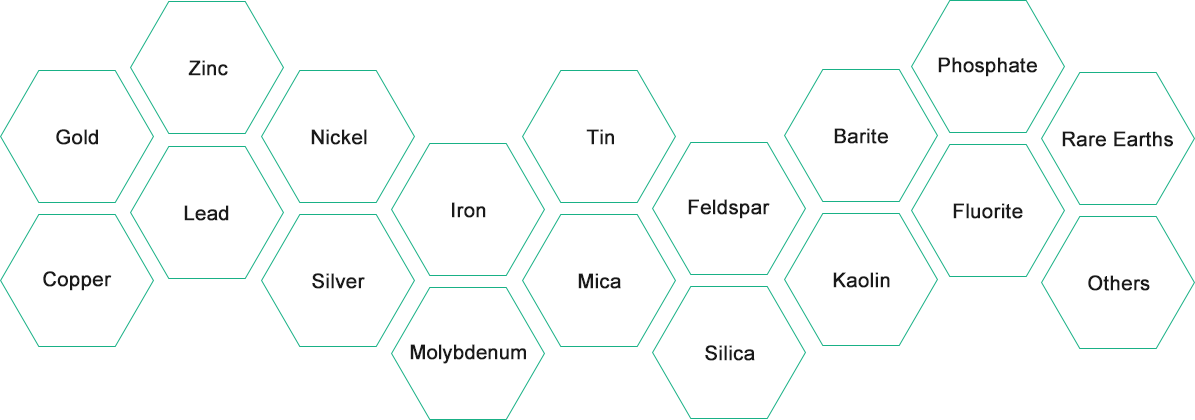

Minerals Processed

CNLITE froth flotation reagents are successfully used to the recovery of the following minerals:

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

Call Us

008613641173523

Call Us

008613641173523

Flotation process is widely used in mineral processing industry. CNLITE froth flotation reagents are widely used in flotation processing plants for different minerals.

We are devoted to increasing benefits to our customers by providing higher mineral recovery or solving other specific needs in the mining process, giving our customers a broad scope to create sustainable, differentiated solutions for a fast-changing world.

Our application expertise and professional flotation laboratories enable us to develop the perfect reagents for various mineral flotation process, design the optimal application system, monitor product performance, and adjust formulations as conditions change.

Primary, secondary and reverse beneficiation

Feed preparation, mineral conditioning, pH control and gangue suppression

Froth stabilization, modification and selective flotation

Foam control

Mineral depression and/or activation

Process difficult ores

Improved process efficiencies

Reduce reagent cost

Better mineral selectivity

Higher grade and recovery at lower collector doses

Better pumping and slurry handling

Reduced mineral loss from foam-overs

Depression specificity

Minimum harm to environment

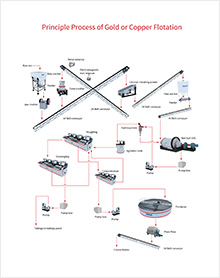

Principle Process of Gold or Copper Flotation

Principle Process of Gold or Copper Flotation

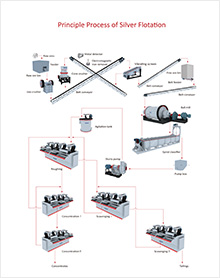

Principle Process of Silver Flotation

Principle Process of Silver Flotation

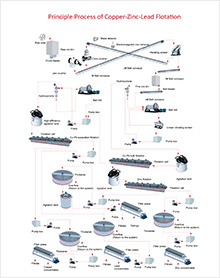

Principle Process of Copper-Zinc-Lead Flotation

Principle Process of Copper-Zinc-Lead Flotation

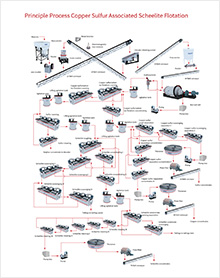

Principle Process of Copper Sufur Associated Scheelite Flotation

Principle Process of Copper Sufur Associated Scheelite Flotation

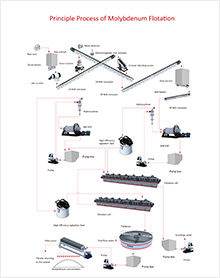

Principle Process of Molybdenum Flotation

Principle Process of Molybdenum Flotation

Principle Process of Chrome Flotation

Principle Process of Chrome Flotation

Principle Process of Fluorite Flotation

Principle Process of Fluorite Flotation

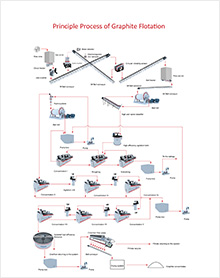

Principle Process of Graphite Flotation

Principle Process of Graphite Flotation

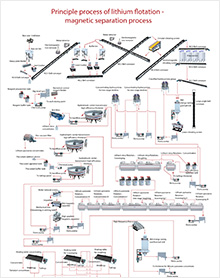

Principle Process of lithium flotation-magnetic separation process

Principle Process of lithium flotation-magnetic separation process

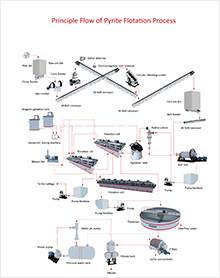

Principle Process of Pyrite Flotation

Principle Process of Pyrite Flotation

Please leave your message here! We will send detail technical info and quotation to you!