-

E-mail

guhaixin0724@gmail.com

E-mail

guhaixin0724@gmail.com

-

Call Us

008613683147042

Call Us

008613683147042

E-mail

guhaixin0724@gmail.com

E-mail

guhaixin0724@gmail.com

Call Us

008613683147042

Call Us

008613683147042

2020-06-05 11:27:16 XinHai Views:183723

With more than 20 years of experience in the processing of gold ore, we have accumulated a wealth of professional knowledge. And we have done many successful projects in many countries. For these years, we're dedicated in providing professional gold extraction solution for different type of gold mine.

【Principle】Gold CIL process (carbon in leach) refers to add activated carbon to the pulp, leach and adsorb gold in the same time. It is an effective way to recover gold, and can reach 99% recovery rate.

【Process】

1. Crushing and Screening

2. Grinding and Classification

3. Agitation

4. Leaching and Adsorption

5. Desorption electrowinning

6. Purified ingot

【Application】High-grade gold ore; Gold ore with associated silver and copper.

【Related Equipment】

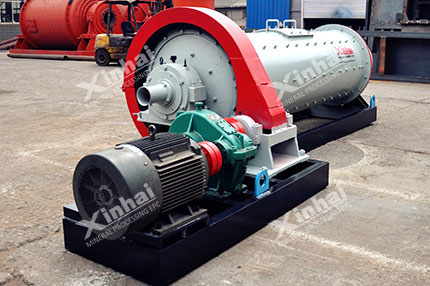

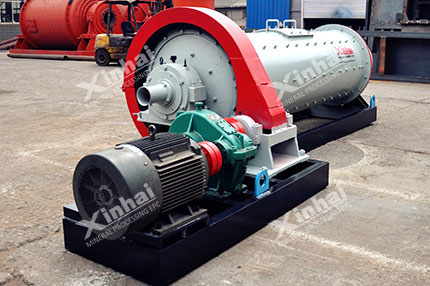

Ball Mill

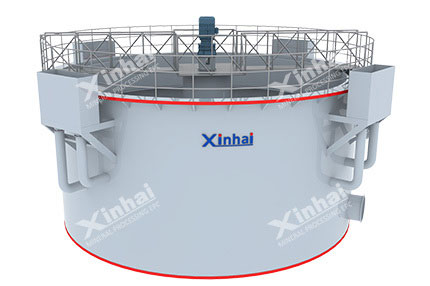

Washing Thickener

Leaching Tank

Desorption Electrolysis System

【Case】

Zimbabwe 700t/d Gold CIL Plant

Malaysia 700t/d Gold CIL Plant

Indonesia 100t/d Gold CIL Plant

Sudan 300t/d Gold CIL Plant

【Principle】Gold CIP(carbon in pulp) Process refers to an unfiltered cyanide carbon slurry process that uses activated carbon to directly adsorb and recover gold from cyanide ore pulp. Generally, carbon adsorption is performed after cyanide leaching is completed.

【Process】

1. Crushing and Screening

2. Grinding and Classification

3. Agitation and Leaching

4. Carbon Adsorption

5. Desorption electrowinning

6. Purified ingot

【Application】Flotation gold concentrate; Mercury amalgamation and gravity separation tailings; Muddled oxidized ore.

【Related Equipment】

Leaching Agitation Tank

Air Lifter

Carbon Screen

Zinc Powder Displacement Device

【Case】

Guinea 6,000t/d Gold CIP Plant

Tanzania 1,200t/d Gold CIP Plant

Mongolia 1,000t/d Gold CIP Plant

Tanzania 600t/d Gold CIP Plant

【Principle】Gold heap leaching refers to pile up low-grade gold ore or flotation tailings on the bottom mat material, and then spray it through the NaCN solution to dissolve the gold in the ore to form a gold-containing pregant liquid and finally refine to recover gold.

【Process】

1. Crushing and Screening

2. Set Heap Leaching Site

3. Heap Spraying and Leaching

4. Carbon Adsorption

5. Zinc Powder Displacement Device Refine

【Application】Low-grade gold ore; Small-scale gold ore.

【Related Equipment】

Jaw Crusher

Agitation Tank for Chemical Reagent

Desorption Electrolysis System

Zinc Powder Displacement Device

【Principle】Tank and vat leaching involves placing ore, usually after size crused and classification, into large tanks or vats at ambient operating conditions containing a leaching solution and allowing the gold to leach from the ore into solution.

【Process】

1. Crushing and Screening

2. Grinding and Classification

3. Pump Slurry Into Vat or Tank

4. Agitation and Leaching

5. Carbon Adsorption

6. Zinc Powder Displacement Device Refine

【Application】Low-grade gold ore; Small-scale gold ore; Flotation tailings.

【Related Equipment】

Slurry Pump

Leaching Tank

Vibrating Screen

Zinc Powder Displacement Device

【Principle】The flotation refers to the process of adding the flotation reagent to the ore slurry to achieve the separation of different minerals. It is use for minerals with abvious physical and chemical differences.

【Process】

1. Crushing and Screening

2. Grinding and Classification

3. Add Flotation Reagent and Mix Pulp

4. Flotation

5. Dewatering and Dry

【Application】Fine gold; Sulfide gold-containing quartz ore; Multi metal gold-containing sulfide ore and carbon-containing ore.

【Related Equipment】

SF Flotation Cell

Agitation Tank for Chemical Reagent

XCF Flotation Machine

Reagent Feeder

【Case】

China 6,000t/d Gold Flotation Plant

Heilongjiang 1,000t/d Gold Flotation Plant

Mexico 1,500tpd multi-metal Flotation Plant

【Principle】Gravity separation refers to the process that separate mineral according to the difference in its specific gravity

【Process】

1. Crushing and Screening

2. Grinding and Desilting

3. Gravity Separation by Shaker/Chute/Jigger/Concentrator

4. Dewatering and Dry

【Application】Alluvial gold sand deposits.

【Related Equipment】

Shaking Table

Spiral Chute

Ball Mill

Concentrator

【Case】

Sudan 10t/h Gold Gravity Separation Plant

Please leave your message here! We will send detail technical info and quotation to you!