-

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

-

Call Us

008613641173523

Call Us

008613641173523

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

Call Us

008613641173523

Call Us

008613641173523

2025-12-15 Views: 817

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

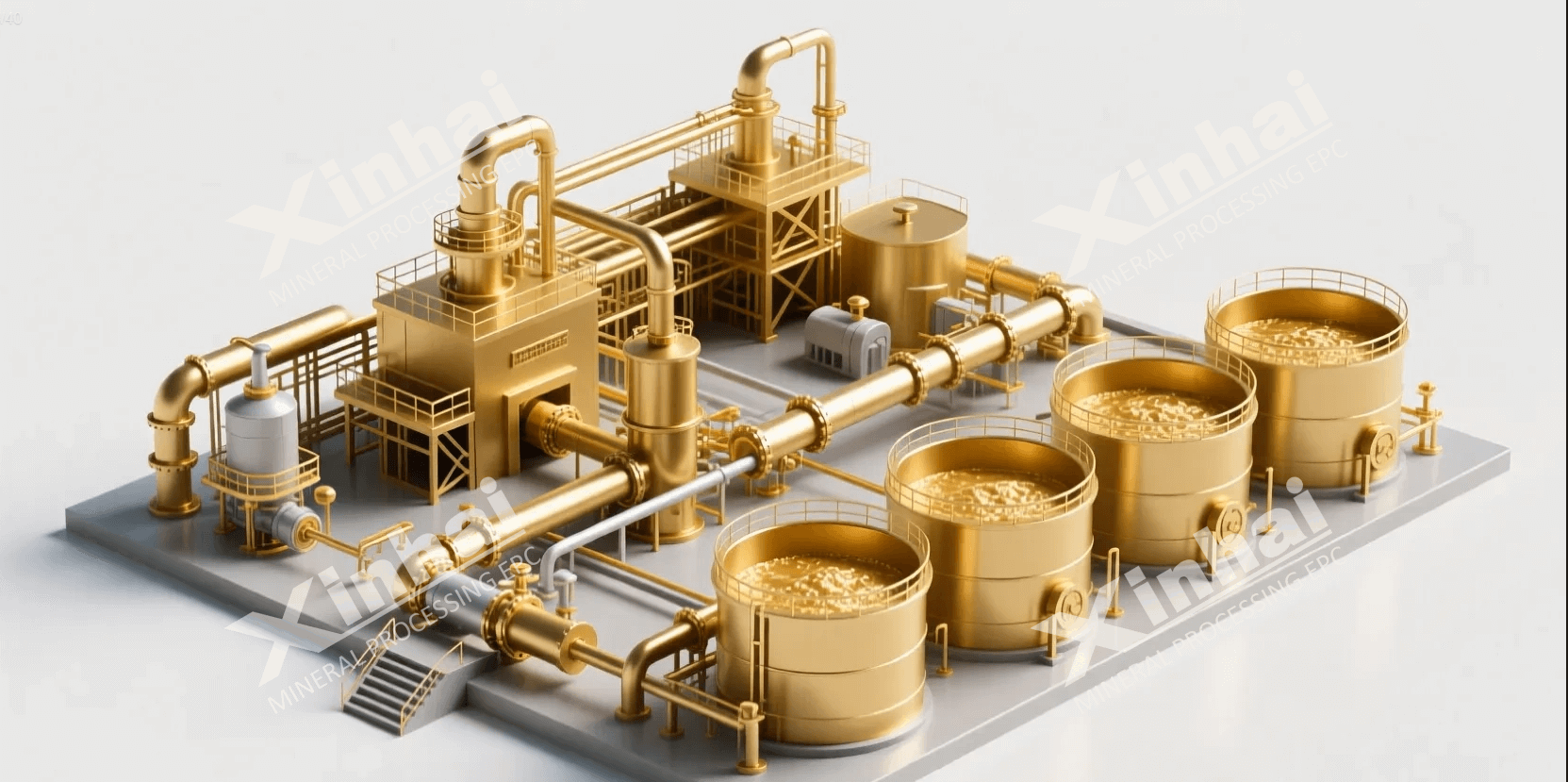

In gold processing plants, the primary methods using activated carbon to "capture" gold from slurry are CIP (Carbon-in-Pulp) and CIL (Carbon-in-Leach). They sound similar and both rely on the gold leaching process, but their underlying principles and suitable applications are distinctly different. Choosing the right one leads to high recovery rates and lower costs; choosing wrong can mean half the result for double the effort. Today, we'll move past complex theories and clearly explain the core differences and selection logic between them.

Understanding the difference can be illustrated with a simple analogy:

CIP (Carbon-in-Pulp) is like a strict relay race. The race has two separate, clear legs: the first leg is the "Leaching Section," where the cyanide solution works to dissolve the gold from the ore, forming a gold-bearing solution. Only after this step is complete does the slurry enter the second leg, the "Adsorption Section," to meet the activated carbon, where gold is adsorbed onto the carbon. Leaching and adsorption are separate, sequential steps.

CIL (Carbon-in-Leach), on the other hand, is like a team collaboration tackling a challenge. From the first tank, cyanide and activated carbon are both present, working side-by-side. They dissolve the gold and immediately adsorb the dissolved gold away. Leaching and adsorption occur simultaneously in the same series of tanks.

This fundamental difference in process design leads to all subsequent variations.

| Feature | CIP (Carbon-in-Pulp) | CIL (Carbon-in-Leach) |

|---|---|---|

| Process Essence | Leach first, then adsorb – a separated flow. | Leach and adsorb simultaneously – an integrated flow. |

| Flow Path | Milling → Dedicated Leach Tanks → Dedicated Adsorption Tanks → Tailings | Milling → Integrated Leach/Adsorption Tank Series → Tailings |

| Working Mode | Like an assembly line; one process finishes before the next begins. | Like a team; two tasks are completed in the same space concurrently. |

| Carbon Addition Point | Added only at the adsorption tank series. | Added towards the end of the tank series, moving counter-current to the slurry flow. |

The CIP process is clear and step-by-step. After the ore is milled, it first undergoes sufficient cyanide leaching in dedicated tanks (often taking 24+ hours) to dissolve as much gold as possible. This creates a "pregnant solution." This solution is then pumped into a series of adsorption tanks where it contacts activated carbon counter-currently, and the gold transfers onto the carbon.

Its main advantages are:

Precise Control: Conditions for optimal leaching and adsorption (e.g., cyanide concentration, pH, carbon density) can be optimized separately without interference.

Best For: Ores with relatively simple, stable mineralogy and fast gold dissolution kinetics. It has more traditional requirements for equipment and management.

The CIL process is more integrated. Cyanide and activated carbon coexist from an early stage in the process. Gold is adsorbed immediately upon dissolution, lowering its concentration in the solution.

This design cleverly solves problems posed by "rebellious" ores:

| Ore Challenge | CIL's Solution |

|---|---|

| Contains preg-robbing carbon | Activated carbon is always present, competing with and overpowering the preg-robbing carbon to capture gold first, significantly reducing losses. |

| Contains easily cyanided metals like copper/zinc | Immediate gold adsorption shortens its solution residence time, reducing wasteful cyanide consumption by these impurities. |

| Desire for shorter construction cycle | Integrated flow often requires less total tank volume and footprint than CIP, potentially offering capital cost advantages. |

Choosing between CIP and CIL isn't about which is more advanced, but which is more suitable for your specific "ingredients." The main decision factors are:

If the ore contains preg-robbing carbon or metals like copper that readily consume cyanide, prioritize CIL. It allows instant adsorption, preventing gold re-loss or excessive cyanide consumption.

If the ore is "clean" and easy to process, both are viable. Then, a comprehensive comparison of investment and operating costs is needed.

CIP may require more total tank volume (leach + adsorption tanks), but carbon loading in the adsorption section is often higher.

CIL has a compact flow, potentially less total tank volume, but tank design must balance both leaching and adsorption conditions.

CIP has a longer flow with separate control points, making it easier to troubleshoot by section.

CIL has integrated operations, simplifying some aspects but requiring higher initial design precision and balanced process control.

Decision Matrix: Choosing the Right Process

| Decision Factor | Lean Towards CIP | Lean Towards CIL |

|---|---|---|

| Ore Type | Simple, free-milling, NO preg-robbing carbon or low base metals | Complex, contains preg-robbers, high copper/arsenic, or high clay content |

| Capital Cost | May need more tanks (separate leach+adsorb) but design is traditional. | Compact flow, potentially less total tank volume/floor space, but tank design is more complex. |

| Process Control | Leach & adsorb parameters can be tuned independently. Easier sectional troubleshooting. | Requires balancing chemistry in-tank. Higher integration, needs good automation. |

| Flexibility | Moderate adaptability to feed grade fluctuations. | Generally more adaptable to ore variability. |

| Project Scale | Suitable for large, medium, or small projects; especially for retrofitting existing leach plants. | Often the preferred choice for new projects, particularly small to medium scale. |

A: There's no absolute answer. For simple ores, both can achieve very high recovery. However, for complex ores containing interfering substances like preg-robbing carbon, the CIL process typically achieves higher recovery because it effectively suppresses the "preg-robbing" phenomenon.

A: Yes, technically feasible. It typically involves introducing cyanide into the front of the adsorption circuit and adjusting the entire system's chemical balance, carbon transfer method, and control strategy. However, this requires detailed engineering assessment and design, not a simple modification.

A: On the contrary. By rapidly removing the gold-cyanide complex, the carbon lowers the gold concentration in solution. From a chemical equilibrium perspective, this actually promotes further gold dissolution, enhancing the leaching kinetics.

A: CIL is often more favored. Its compact flow requires less footprint, potentially lower capital investment, and it generally adapts better to ore variability.

In summary, choosing between CIP and CIL is a contest of "suitability" and "optimization." CIP is the stable, reliable classic, while CIL is the modern tool for tackling complexity and improving efficiency. The core of the decision starts with a deep understanding of your ore's mineralogy.

If you are planning a new project or seeking to optimize an existing circuit, we are here to help. We offer comprehensive technical support, from ore amenability testing and process flow comparison to customized chemical solutions. Whether addressing preg-robbing challenges or optimizing your CIL process parameters, we can provide expert insights.

Contact us today to obtain a preliminary process assessment tailored to your ore characteristics. Let us use our specialized knowledge to help you unlock greater gold recovery value and economic returns.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!