-

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

-

Call Us

008613641173523

Call Us

008613641173523

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

Call Us

008613641173523

Call Us

008613641173523

2025-12-17 Views: 338

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

As a mine owner, your core concern is always how to extract more gold from every ton of ore with lower costs, higher efficiency, and more controllable risk. In the Carbon-in-Pulp (CIP) or Carbon-in-Leach (CIL) process, desorption and electrowinning are the critical bottlenecks connecting "adsorbed gold" to the "final gold bar". The efficiency of these two stages directly determines the speed of your cash flow and the final few percentage points of your overall recovery rate. This article will bypass complex chemical formulas and analyze how to optimize these "two golden steps" from operational and financial perspectives.

For mine owners, understanding how gold moves from carbon to metal is crucial. It's not just chemistry; it dictates your cash flow.

In CIL/CIP processes, loaded carbon is transferred to desorption tanks.

· Principle: High-temperature, high-concentration sodium cyanide/sodium hydroxide solutions break the bond between gold and carbon.

· Output: Pregnant Solution (rich liquid) containing high concentrations of gold cyanide complexes.

This is where solution turns into solid metal.

· Principle: Under a direct electric field, gold ions gain electrons at the cathode (usually steel wool) and are reduced to metallic gold.

· Output: Anode Slimes (cathode gold sheets), which are later smelted into gold bars.

Loaded carbon is your mobile gold vault, but the gold inside is a "frozen" asset. The purpose of desorption is to efficiently and quickly "liquidate" these assets into a solution. Choosing which desorption method is a key strategic investment decision that impacts your operating costs, safety risks, and environmental pressures.

The table below provides a clear comparison of mainstream desorption options, precisely the trade-offs you need to weigh as a decision-maker:

Solution Type | Operating Mode | Key Advantages | Main Drawbacks | Best Use Case |

High-Pressure | Autoclave, ~150°C | Highest recovery, proven tech | Very high energy use, costly equipment, safety risk | Very large mines with cheap power |

Alcohol-Based | Adds ethanol/methanol, heated | Fastest stripping, quick carbon turnaround | High reagent cost, flammable | Large mines prioritizing speed with strong safety controls |

Eco-Friendly, Atmospheric | Special reagent, ~90°C, atmospheric | Most energy-efficient & safe, simple, eco-compliant | Reagent cost consideration | Mines focusing on total cost, safety & sustainability (e.g., South America, Africa) |

Insight for Mine Owners: In an era of high electricity and fuel prices, energy consumption is pure profit. A seemingly higher initial investment in an atmospheric low-temperature system can often recoup the extra cost within 1-2 years through long-term energy savings and reduced safety risks. More importantly, it provides a more stable, predictable operating environment, minimizing unexpected shutdowns due to safety or environmental issues.

The pregnant solution produced by desorption is valuable, but still a liquid. Gold electrowinning is your mine's "mini mint," directly converting the gold in solution into high-purity, smeltable gold slime. The efficiency of this stage determines the quality of your final product and the speed of capital return.

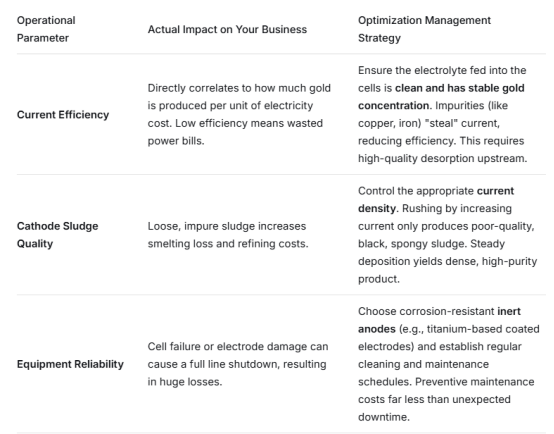

Electrowinning efficiency is not determined by a single factor but by a set of operational parameters that require fine-tuning:

Critical Link: You must view desorption and electrowinning as an inseparable profit unit. Inefficient desorption produces "dirty," fluctuating pregnant solution, which cripples your electrowinning house—low current efficiency, poor sludge quality, accelerated equipment wear. Ensuring stable and efficient desorption is a prerequisite for optimal electrowinning performance and lower processing cost per ton.

1. Q: I'm considering expanding or upgrading my recovery plant. Should I prioritize investing in the desorption system or the electrowinning system?

A: Prioritize investment in the desorption system. An efficient, energy-saving, stable desorption system provides the best possible "feedstock" for the entire back-end (electrowinning, smelting). This is akin to upgrading the refinery before the engine for greater overall performance. A successful desorption upgrade can simultaneously improve electrowinning efficiency and final recovery.

2. Q: My mine has unstable and expensive power. What are the concrete solutions?

A: This is a core pain point for many owners in Africa and South America. The solution is two-fold: First, opt for an atmospheric low-temperature desorption process to drastically reduce steam demand. Second, equip the electrowinning system with smart rectifiers and buffer power supplies to handle voltage fluctuations. Also, optimize cell design for lower voltage operation. When selecting equipment, "tolerance to fluctuation" and "low energy consumption" must be key criteria.

3. Q: How do I balance environmental compliance pressure with cost control?

A: Modern eco-friendly desorption reagents (like the Cnlite series) are designed for this very purpose. They avoid adding highly toxic cyanides or alcohols, making wastewater easier to treat, thereby reducing your end-of-pipe environmental treatment costs and regulatory risks from the source. While the unit price of the reagent needs evaluation, the Total Cost of Ownership (TCO)—factoring in saved energy, reduced risk of environmental fines, and enhanced corporate social responsibility (beneficial for community relations and long-term operation)—is often more competitive.

4. Q: For small to medium-sized mines, is it cost-effective to build our own electrowinning house, or is outsourcing the pregnant solution better?

A: This depends on your logistics, security, and need for cash flow control. Building in-house increases control and final profit but requires a technical team and maintenance costs. Outsourcing is hassle-free, but it sacrifices a portion of profit. If you really want to build your mines fast and hassle-free, our Xinhai EPC service can fit your needs. Today, modular, containerized small-scale integrated electrowinning units offer a new option for small and medium mines. They have a lower investment threshold, faster installation, and simplified operation, allowing you to quickly bring the final gold production under your control. To satisfy some of our customers’ demands, we could also provide modular electrowinning units.

Esteemed mine owner, in the complex business of gold mining, the geological grade is a given talent you cannot control, but the plant recovery rate is a direct reflection of your management capability and technical decisions. Desorption and electrowinning, as the "final refiners" in the recovery chain—every bit of efficiency gained here translates directly into increased net profit on your financial statements.

Choosing the right process is not just a technical issue; it is a strategic financial decision. It's about how you reduce the production cost per ounce of gold, how you manage operational risk, and how you build a more sustainable, resilient mining asset.

If you wish to re-evaluate the profit potential of your existing recovery plant, or are seeking the most reliable and economical integrated desorption and electrowinning solution for a new project, the Cnlite team can be your professional technical partner. We specialize in providing Cnlite reagent solutions, customized EPC service in processing based on specific ore characteristics and local operating conditions for global mine owners, helping you convert underground resources into bank wealth more efficiently and safely.

Contact our expert team today for a preliminary benefit analysis tailored to your mine's situation.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!