-

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

-

Call Us

008613641173523

Call Us

008613641173523

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

Call Us

008613641173523

Call Us

008613641173523

2026-01-28 Views: 66

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

Gold CIP, short for Carbon-In-Pulp, is a staple technique for gold extraction using cyanidation. At its core, this method relies on activated carbon to adsorb monovalent gold cyanide complexes [KAu(CN)₂]—a step that comes right after cyanide leaching breaks down gold-bearing ores or materials.

CIP works best with specific gold-rich feeds: flotation gold concentrates, oxidized gold deposits heavy in clay, mercury-amalgamated substances, and leftover tailings from gravity separation. Its ability to handle these tricky feedstocks is why it’s still a top pick for modern gold processing operations worldwide.

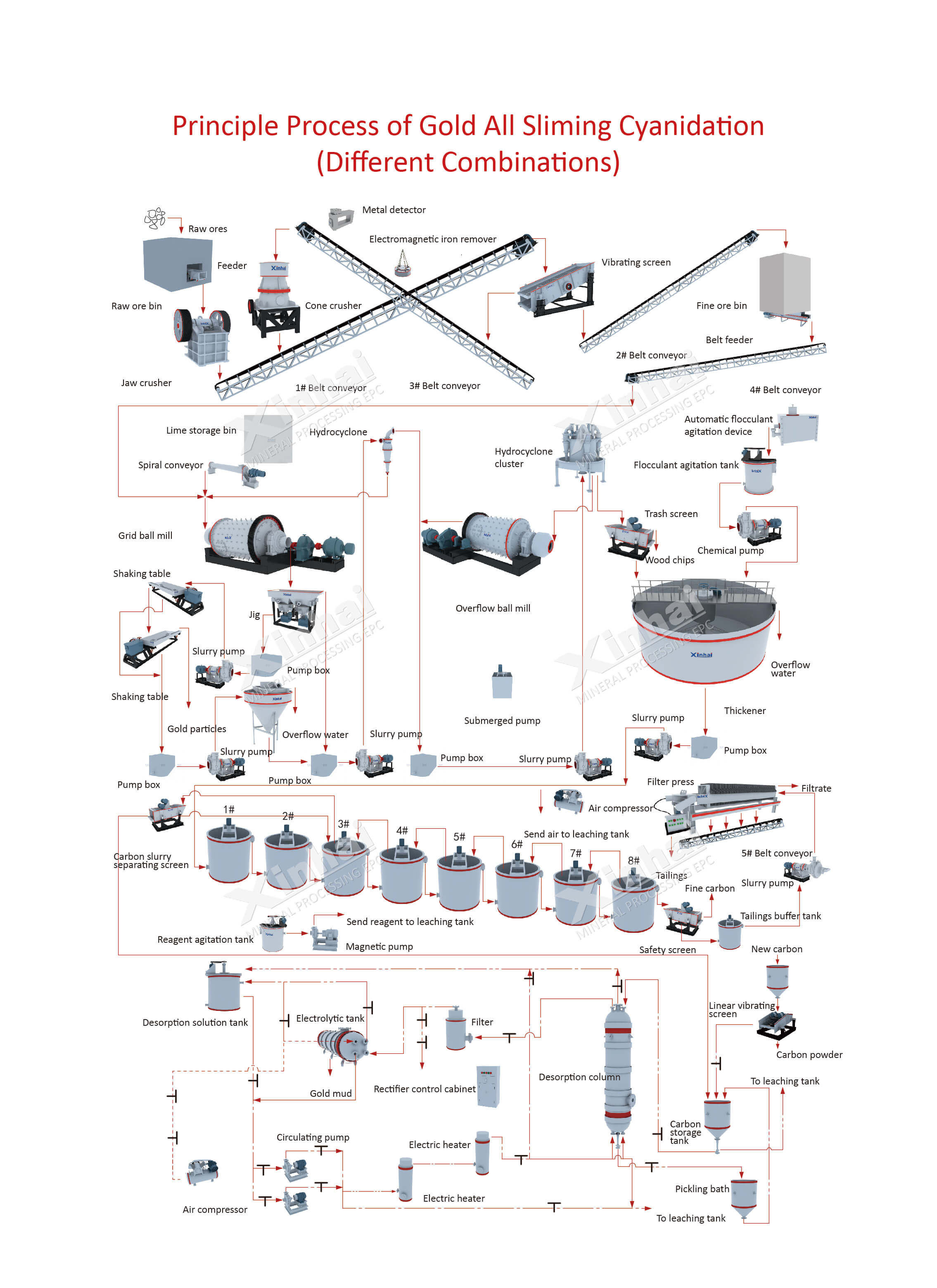

The gold CIP process is split into seven key, sequential steps—each one critical to pulling as much gold as possible from the ore. These steps are: leaching pulp preparation, cyanide leaching, carbon adsorption, loaded gold carbon desorption, electrolytic recovery of gold mud, barren carbon regeneration, and leaching pulp treatment.

First, gold-bearing materials get ground down to a size that works for cyanidation—usually finer than 28 mesh. This grinding is non-negotiable; it makes sure gold particles are exposed enough to react with leaching chemicals later on. Next, debris like sawdust is cleared out to avoid messing up subsequent steps. The material then goes through concentration and dehydration to get the leaching pulp density to 45%–50%—a sweet spot that keeps reactions efficient without complicating operations.

Cyanide leaching here follows standard industry practices, most often using 5 to 8 agitated mixing tanks. These tanks keep the pulp and cyanide reagents moving, ensuring every gold particle has a chance to dissolve into the cyanide solution.

Once leaching is done, the pulp is sent to agitated adsorption tanks—also called carbon slurry tanks. Activated carbon is added to these tanks, and it latches onto gold in the cyanide solution, forming what’s known as loaded gold carbon. When adsorption is finished, a carbon extraction screen separates the gold-laden carbon from the pulp: the loaded carbon moves to the next stage, while the now-barren pulp heads for further treatment.

Inside a closed system, loaded gold carbon undergoes fast desorption and electrolysis under high heat and pressure, resulting in gold mud and barren carbon (carbon with no gold left). Industry currently uses four main desorption methods:

Desorption with hot caustic sodium cyanide solution;

Desorption using low-concentration caustic sodium cyanide solution mixed with alcohol;

Desorption with acidic sodium cyanide solution under heated, pressurized conditions;

Desorption via high-concentration caustic sodium cyanide solution.

As part of that same closed-system process, the gold released during desorption is recovered via electrolysis as gold mud, along with barren carbon. The collected gold mud only needs simple pickling and impurity removal to get rid of non-gold materials. After that, it can be smelted into gold ingots for further refining or sale.

Barren carbon from desorption first soaks in a 1.5%–2.0% nitric acid solution for 24 hours. This dissolves calcium deposits and other impurities that build up on the carbon. It’s then rinsed with clean water until it hits a neutral pH. The regenerated carbon goes back into the adsorption cycle—cutting down on costs and making the process more resource-efficient.

The barren pulp (after carbon is removed) is run through a filter press to separate solid slag from water. The filtered slag is disposed of using standard stacking protocols, while the recovered water is reused in the production process. This aligns with today’s focus on sustainable, eco-friendly mineral processing practices.

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!