-

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

-

Call Us

008613641173523

Call Us

008613641173523

E-mail

xhcnlite@ytxinhai.com

E-mail

xhcnlite@ytxinhai.com

Call Us

008613641173523

Call Us

008613641173523

2025-04-29 Views: 6481

Warm Tip: If you want to know more information, like quotation, products, solutions, etc., please Click here ,and contact us online.

The Carbon-in-Leach process is a gold extraction method that combines leaching (dissolving gold from ore) and adsorption (collecting dissolved gold) into a single step. Unlike older techniques, CIL uses activated carbon to capture gold directly from the slurry (a mix of crushed ore and water), making it faster and more efficient.

This method is widely used in modern mining because it reduces costs, improves recovery rates, and simplifies the workflow. But how exactly does it work? Let’s explore the CIL process flow diagram step by step.

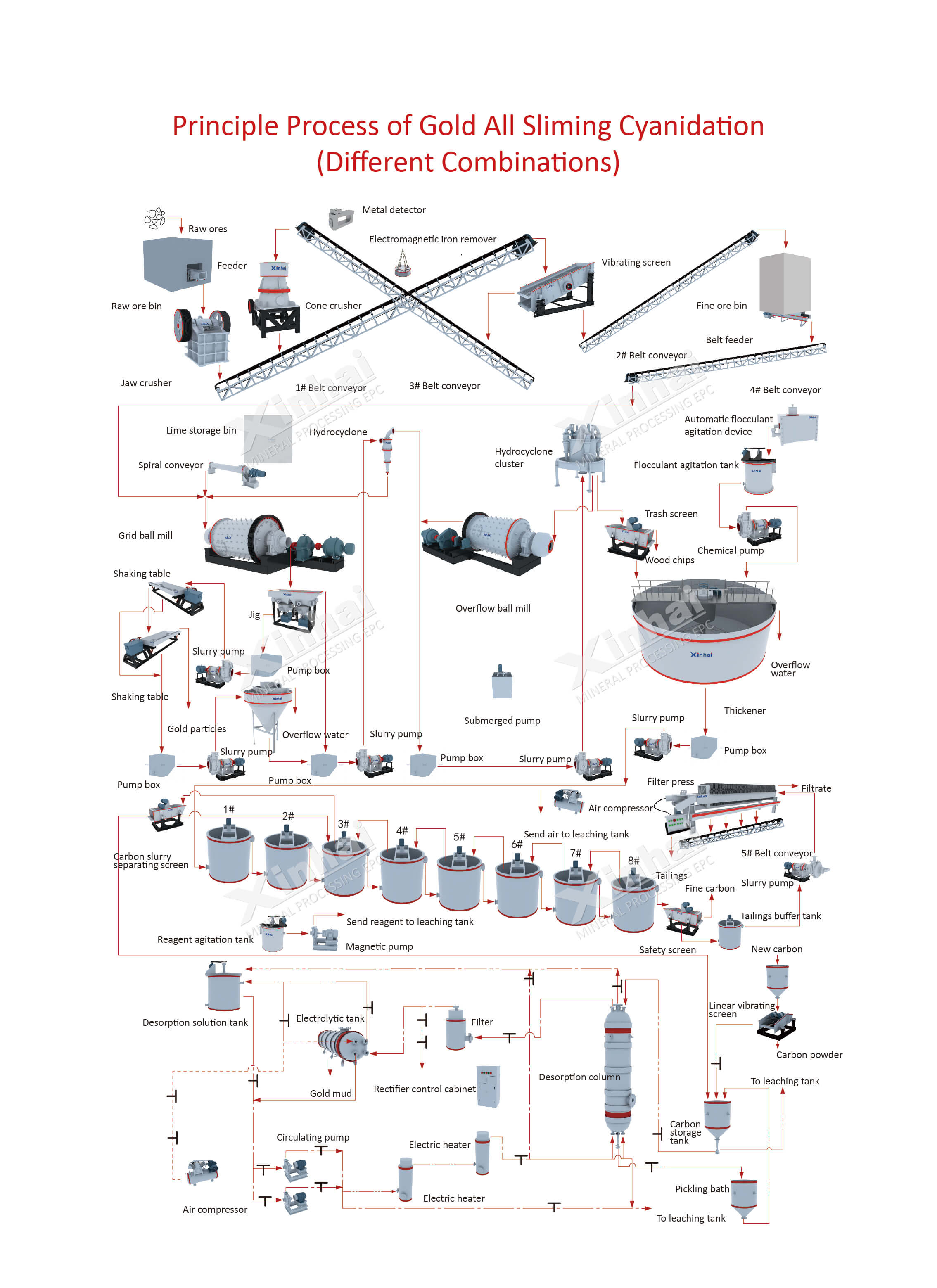

Here’s a simplified breakdown of the CIL process stages:

Raw gold ore is first crushed into smaller pieces and then ground into a fine powder. This step increases the surface area of the ore, making it easier for chemicals to dissolve gold particles later.

The ground ore is mixed with water and cyanide in large tanks called leach reactors. Cyanide dissolves the gold, forming a gold-cyanide solution. Activated carbon is added directly to these tanks, where it immediately adsorbs the dissolved gold—like a magnet attracting iron filings. This simultaneous leaching and adsorption prevent “preg-robbing,” where natural carbon in the ore steals gold before it can be recovered.

After adsorption, screens separate the gold-loaded carbon from the leftover slurry (now called tailings). The carbon moves to the next stage, while the tailings are treated to remove cyanide and safely stored.

The gold-loaded carbon is washed in a high-temperature, high-pressure chamber to release the gold into a solution. This solution undergoes electrowinning, where an electric current turns dissolved gold into solid gold bars.

Used carbon is reactivated by heating it in a kiln, allowing it to be reused in the process. This recycling reduces waste and operational costs.

Tailings are filtered, detoxified, and stored in secure facilities to prevent environmental harm. Modern CIL plants often recycle water from this stage, enhancing sustainability.

Higher Efficiency: Combining leaching and adsorption speeds up gold recovery.

Cost-Effective: Reusing activated carbon reduces material costs.

Environmentally Safer: Modern CIL plants recycle water and treat tailings responsibly.

Flexibility: Effective for both high-grade ores and complex ores containing silver or copper

The Carbon-in-Pulp (CIP) process is similar but separates leaching and adsorption into two steps. In CIL, both happen simultaneously, cutting downtime and improving gold recovery rates.

Q: Is cyanide in CIL safe?

A: It is not very safe. Sodium cyanide itself is highly toxic, both to the environment and to people's bodies (you can often see news about rivers in some areas being contaminated by sodium cyanide and fish dying). Therefore, we try to reduce the demand for it as much as possible, so the supply chain for the production of sodium cyanide will gradually decrease. It is recommended to use environmentally friendly gold leaching reagent, CNLITE can replace sodium cyanide. If you need or want to be an agent, please contact us for more information.

Q: Can CIL handle low-grade ores?

A: Absolutely. CIL is effective for ores with gold concentrations as low as 1 gram per ton.

Q: How long does the CIL process take?

A: A full cycle—from crushing to gold recovery—typically takes 24–48 hours, depending on ore type

Tanzania 1200t/d Gold CIL Plant

Mongolia 3 Million t/a Gold Heap leaching Plant

Guinea 15,000t/d Gold Gravity Separation and CIP Plant

Is CIP or CIL more suitable for your mine? Please analyze it according to the specific situation. If you are not sure, you can always ask us, we are waiting for your question!

No. 188, Xinhai Street, high-tech Industrial Park, Fushan District, Yantai, Shandong, China.

Please leave your message here! We will send detail technical info and quotation to you!